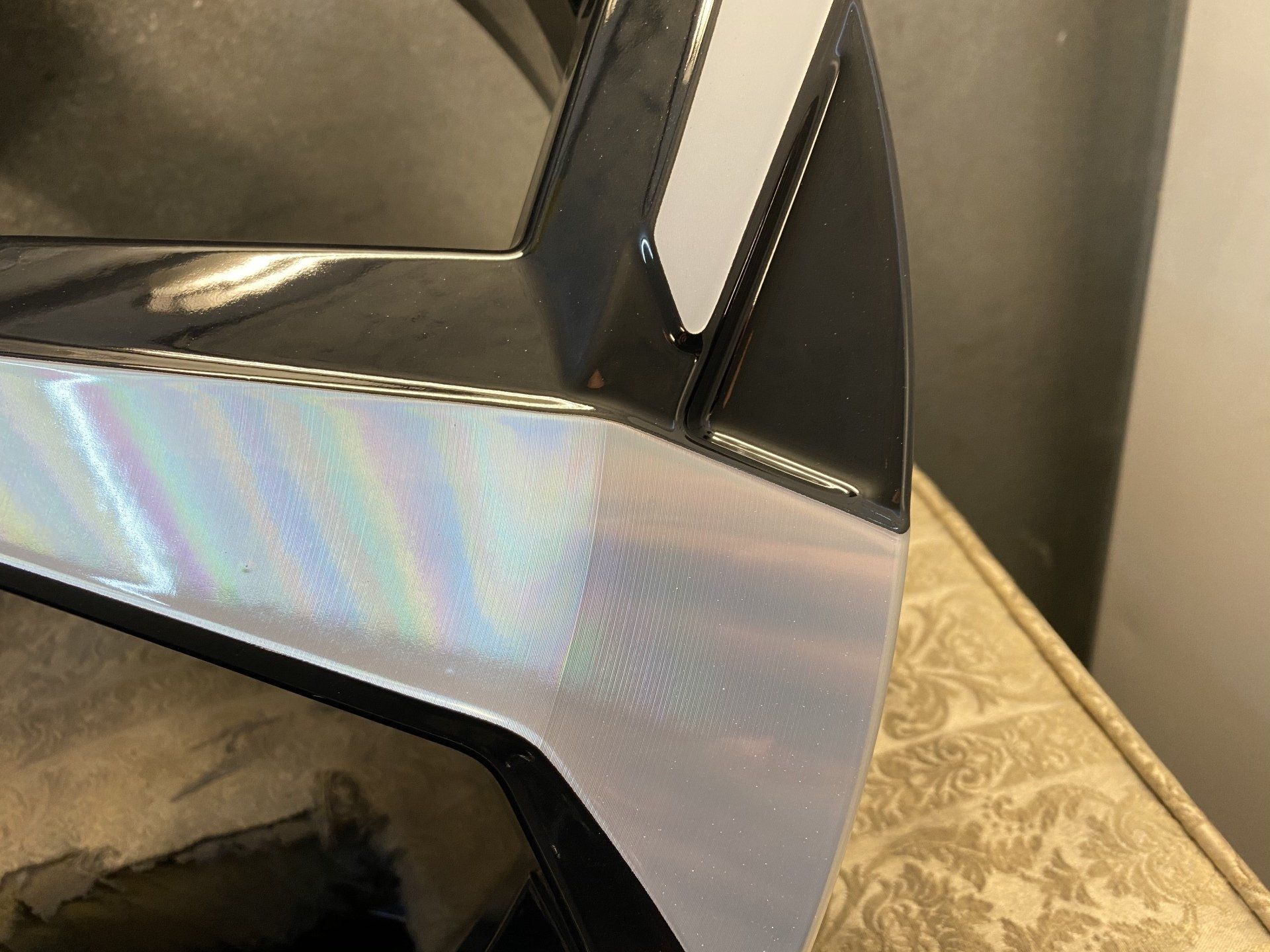

Full custom Refurbishment in High Power Silver

01 /

S1 alloys Chester full repair and full factory restoration

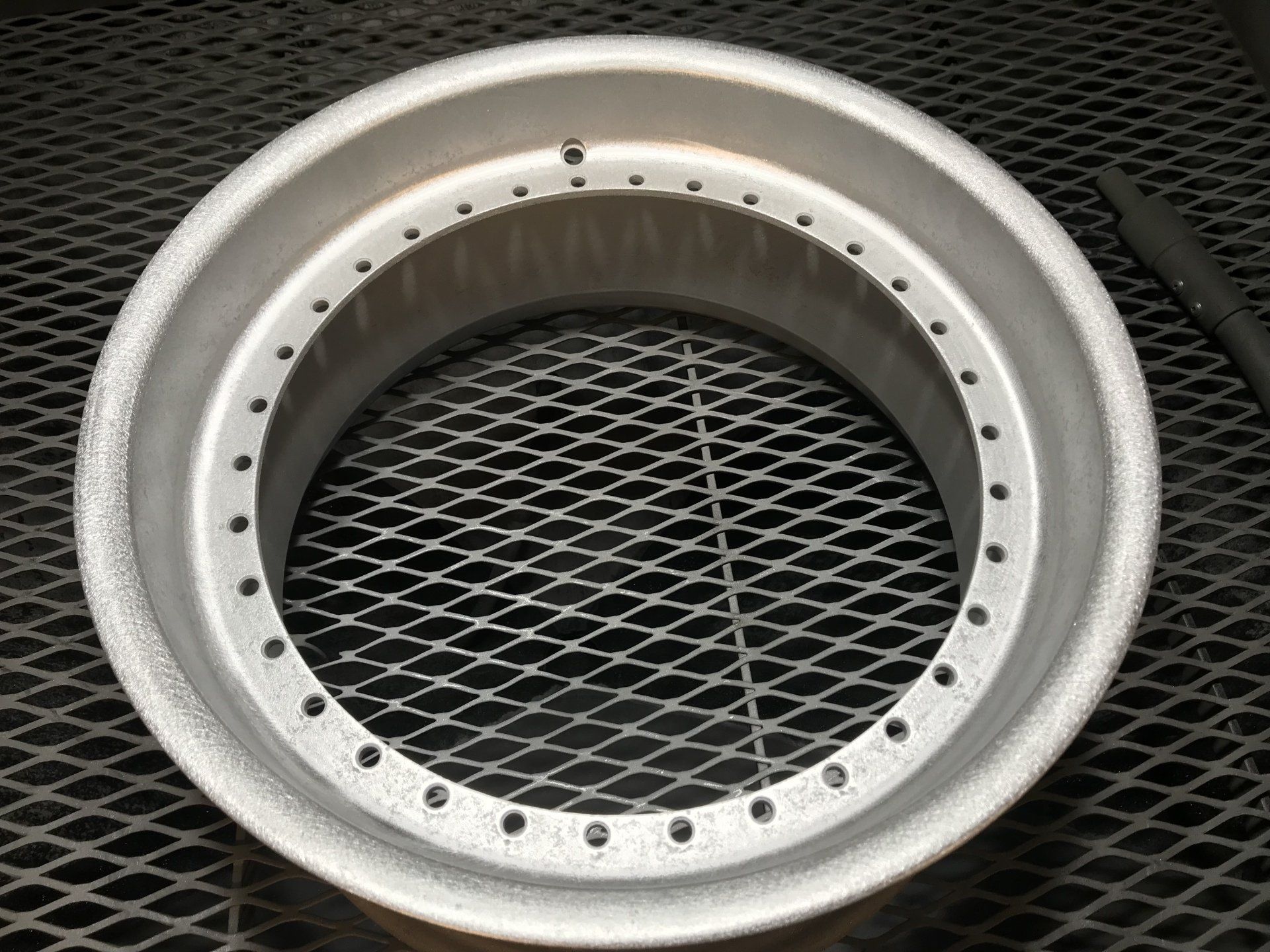

So what's involved? There's lots of reasons why new alloy wheels end up battered and damaged What we do is put those alloy wheels through a defined process of repair/refurbishment,The first refurbishment stage is we must remove as much dirt, grime , grease as possible Then We'll chemically strip the wheels in the latest hot stripping system followed by surface preparation using different types of blasting media this will remove corrosion from the alloy,

The next refurbishment stage is to remove as much corrosion as possible from the face, The most effective way is to turn the alloys on a lathe using a pre-programmed profile of your particular wheel. This process removes a fine layer of alloy exposing a fresh new look for the wheel, we then blast over the face and finish by hand,For safety reasons we won't refurbish wheels that have already been fully refurbished a number of times.The next refurbishment stage is to high pressure steam clean the alloy to remove any media, then we place the alloys in the oven for heat treatment which removes gasses trapped inside the alloys

The next refurbishment process is to coat the wheel, we use a zinc or epoxy primer to give the alloys added protection against corrosion, then we add the colours/effects, There are a several thousand ways you can finish a wheel but the basics are as follows:

We powder coat and paint the alloys,We apply a good layer of polyester or polyethylene lacquer to give the colours/effects protection against the elements.

If your wheel is two or three toned, then we can handle those too by using a mixture of masking and turning to get the required result. Infact, no matter what your wheel looked like, we can get it exactly how it was or do a completely new S1 alloys custom finish for you,The alloys are then placed in the oven for 20 mins at temperatures between 180/200 degrees.Once the alloys have been left to cool overnight we apply by hand a wax/sealer to make yours alloy wheels easier to clean and more importantly to keep the brake dust build up low.

The results and 1000's of very happy customers over the years prove that this process is the only way to get your old alloy wheels back into that showroom condition.

All S1 alloys Chester full refurbishments and repairs carry a 2 year guarantee excluding diamond turn, cosmetics and crack repairs.

Follow us